Creating A Difference

Roofing Malaysia Experts – Asia Jaya Sepadu Sdn Bhd

Asia Jaya Sepadu is a leading roofing and decking supplier Malaysia, trusted for delivering high-performance materials across residential and commercial projects. Our top products include asphalt roof shingles Malaysia, shingles roof Malaysia, shingles roof supplier Malaysia, metal roofing, metal roof Malaysia, Metal Roofing Malaysia, and Roof supplier Malaysia solutions.

We also specialize in outdoor timber decking Malaysia for stylish outdoor spaces, and concrete reinforcement fibre to strengthen all types of concrete work. Whether you're a contractor or homeowner, we’re your go-to choice for quality materials, expert support, and reliable delivery.

Choose Asia Jaya Sepadu – your trusted name for all things roofing Malaysia.

Asphalt Roof Shingles, Decra Metal Roofing & Outdoor Timber Decking Solution Provider in Malaysia

Asphalt Roof Shingles, Decra Metal Roofing & Outdoor Timber Deck Solution Provider in Malaysia

Our innovative way of design for your home and landscapes. Simple but aesthetics is what we applied in our concept of design. From architectural roof to floor decking, we ensure to meet every aspect of your needs. Talk to us for a quote or free consultation.

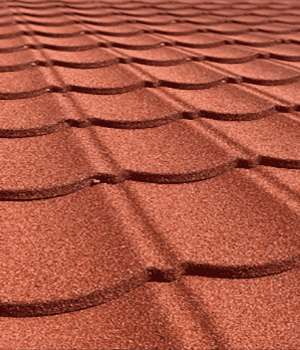

Asphalt Roof

Shingle

Asphalt roof shingle must be supplied with the right accessories-starter, hip, ridge, vent, valley & flashings

Decra Metal

Roofing

Decra Metal Roofing is durable, lightweight, and energy-efficient, lasting over 50 years while reducing costs.

Outdoor Timber

Decking

Belian Wood is a hardwood tree that does NOT belong to the dipterocarp group and is known for its durability.

Wood plastic

composites (WPC)

Wood-plastic composites (WPCs) are made from wood fibers and thermoplastics, with optional fillers.

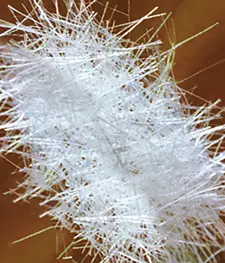

Concrete

Reinforcement Fibre

Fiber reinforced concrete is a durable, high-performance cement composite with dispersed fiber reinforcement

Why customers rely on us for Roofing & Decking?

Premium

Quality Materials

Extensive

Product Range

Expert Guidance & Support

Competitive

Pricing

Commitment to Sustainability

Reliable Delivery & Service

Weatherproof &

Durable

Dependable & Reliable

Request a Quote Today!

Ready to start your next project with Asia Jaya Sepadu Sdn. Bhd.? Whether you’re looking for roofing solutions or timber decking, we’re here to help. Contact us to get a free, no-obligation quote. Our team is here to offer advice, answer questions, and guide you through the selection process.

Creating A Difference

Asphalt Roof Shingles, Decra Metal Roofing & Outdoor Timber Decking Solution Provider in Malaysia

Asphalt Roof Shingles, Decra Metal Roofing & Outdoor Timber Deck Solution Provider in Malaysia

Our innovative way of design for your home and landscapes. Simple but aesthetics is what we applied in our concept of design. From architectural roof to floor decking, we ensure to meet every aspect of your needs. Talk to us for a quote or free consultation.

Asphalt Roof

Shingle

Asphalt roof shingle must be supplied with the right accessories-starter, hip, ridge, vent, valley & flashings

Decra Metal

Roofing

Decra Metal Roofing is durable, lightweight, and energy-efficient, lasting over 50 years while reducing costs.

Outdoor Timber

Decking

Belian Wood is a hardwood tree that does NOT belong to the dipterocarp group and is known for its durability.

Wood plastic

composites (WPC)

Wood-plastic composites (WPCs) are made from wood fibers and thermoplastics, with optional fillers.

Concrete

Reinforcement Fibre

Fiber reinforced concrete is a durable, high-performance cement composite with dispersed fiber reinforcement

Why customers rely on us for Roofing & Decking?

Premium

Quality Materials

Extensive

Product Range

Expert Guidance & Support

Competitive

Pricing

Commitment to Sustainability

Reliable Delivery & Service

Weatherproof &

Durable

Dependable &

Reliable

Request a Quote Today!

Ready to start your next project with Asia Jaya Sepadu Sdn. Bhd.? Whether you’re looking for roofing solutions or timber decking, we’re here to help. Contact us to get a free, no-obligation quote. Our team is here to offer advice, answer questions, and guide you through the selection process.

Asphalt Roof Shingles, Decra Metal Roofing & Outdoor Timber Deck Solution Provider in Malaysia

Our innovative way of design for your home and landscapes. Simple but aesthetics is what we applied in our concept of design. From architectural roof to floor decking, we ensure to meet every aspect of your needs. Talk to us for a quote or free consultation.

Asphalt Roof

Shingle

Asphalt roof shingle must be supplied with the right accessories-starter, hip, ridge, vent, valley & flashings

Decra Metal

Roofing

Decra Metal Roofing is durable, lightweight, and energy-efficient, lasting over 50 years while reducing costs.

Outdoor Timber

Decking

Belian Wood is a hardwood tree that does NOT belong to the dipterocarp group and is known for its durability.

Wood plastic

composites (WPC)

Wood-plastic composites (WPCs) are made from wood fibers and thermoplastics, with optional fillers.

Concrete

Reinforcement Fibre

Fiber reinforced concrete is a durable, high-performance cement composite with dispersed fiber reinforcement

Why customers rely on us for Roofing & Decking?

Premium

Quality Materials

Extensive

Product Range

Expert Guidance & Support

Competitive

Pricing

Commitment to Sustainability

Reliable Delivery & Service

Weatherproof &

Durable

Dependable &

Reliable

Request a Quote Today!

Ready to start your next project with Asia Jaya Sepadu Sdn. Bhd.? Whether you’re looking for roofing solutions or timber decking, we’re here to help. Contact us to get a free, no-obligation quote. Our team is here to offer advice, answer questions, and guide you through the selection process.